Military grade materials are an essential component in defense and security. These materials, mainly steel, are used in anything from tanks to armored vehicles. Military and ballistic grades of steel go through a highly detailed manufacturing process with many tests to see if they meet military standards.

As they are used in military defense and security, mil-grade components must be thoroughly tested to ensure high quality and integrity. This article will provide a simple guide to military grade materials by outlining three different aspects of the industry.

First, you’ll learn what commercial-grade armor is. You’ll also learn about military and ballistic steel. In the third section of this article, you’ll understand the uses of military grade materials.

Let’s get into it.

Commercial grade armor lies in between abrasion-resistant grades and military-certified grades.

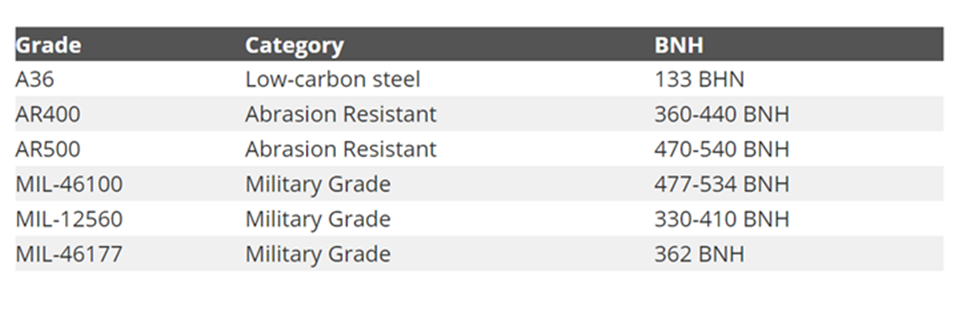

BHN or Brinell Hardness Number is the metric used to measure the hardness of military materials, shown on the right-hand side of the chart. Each material is also given a specific grade, as shown on the left-hand side of the table below.

As you can see, the BHN of some abrasion-resistant materials is actually higher than that of military-grade steel. Commercial grade armor has a BHN of around 400-500. However, the number that really matters is the grade

The grade considers all components, not just hardness. The most critical aspect when looking at military materials is ballistic protection. In the case of commercial grade components, these are classified as capable of providing ballistic protection but not to the level of military combat. In other words, they cannot be used in military applications.

However, there are other uses for commercial-grade armor.

It is slightly more expensive than abrasion-resistant grades but less expensive than military-certified grades. Commercial-grade components are then ideal for those requiring ballistics but find military grade materials expensive. Projects like bank vaults, body armor, or even armored cars for currency transportation all require a certain level of ballistic protection.

Abrasion-resistant material cannot provide ballistic protection, and military-grade steel is often too expensive for other civilian applications. So, commercial grade armor offers the perfect compromise for a project like bank vaults. It is strong enough to provide ballistic protection and is much more affordable than military-grade steel.

The main focus of military-grade standards is primarily on two criteria:

It is important to note that grading is based on a combination of these metrics. As discussed above, some abrasion-resistant materials have a similar or even higher BHN than military-grade steel. However, the ballistic limit aspect sets military-grade steel apart from the rest.

The ballistic limit of a material is determined using several tests at each design stage, carried out by a mil spec supplier. These tests aim to identify the velocity and power levels at which a target would wholly and partially penetrate the steel. For steel to be certified, it must withstand a certain velocity level.

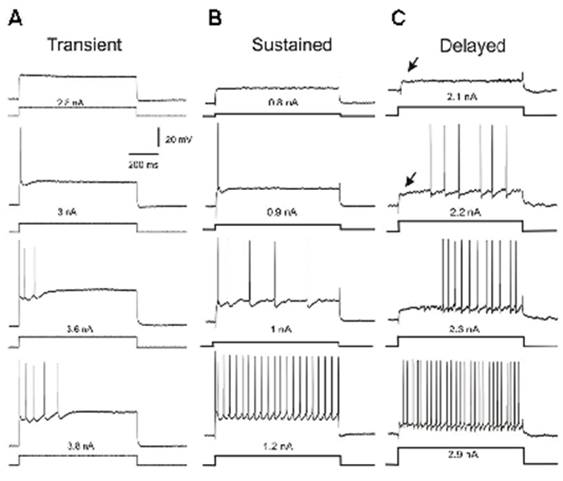

Military-grade steel is also tested for its ability to withstand different firing patterns. There are also tests for different types of ballistics. These include controlled, transient, sustained, and delayed firing patterns (see diagram below).

So, military-grade steel is not only tested to see how much force it can withstand from one shot. It is also tested to ensure it can cope with continuous fire in different patterns. Regarding mil spec standards, this is a vital element of the testing.

Mil spec materials need to be durable and capable of withstanding an onslaught. For example, you may think a material more easily damaged from an initial shot is not helpful for military combat. However, if it is more durable in the face of projectile firing patterns, it may be more valuable than a harder material that can’t cope with rapid fire.

Testing for different firing patterns helps determine what the materials should be used for. We will now discuss the uses of military-grade armor in further detail.

Steel is a crucial material for the defense supplies that protect the armed forces. Common examples of military applications include:

So, it is used as protection across the board in military combat, underwater, on the ground, and in the air.

The ballistic properties of mil-spec materials allow them to protect the armed forces in combat. This is why steel is used in manufacturing all military vehicles and transportation devices to protect the armed forces during the battle. Providing protection is the most important use of military grade steel in combat

However, military grade materials are not only used for protection. It is also used to manufacture weaponry, such as artillery. Artillery weapons are large, high-caliber guns used for long-range fire. Mil-grade components are required to cope with the force and velocity created by such a high-caliber weapon.

Although commercial-grade armor cannot be used in military combat, there are several other uses for this type of material. As mentioned above, commercial-grade armor can be used for bank vaults, vehicles used for currency transport, and body armor.

However, it is also useful for construction and infrastructure-based projects. Projects like bridges, tunnels, pipelines, and railroad tracks rely on steel. It is flexible enough to suit various needs and provides a cost-effective alternative to military grade materials.

In summary, commercial-grade armor isn’t quite a military-certified material and cannot be used to protect to the level of military combat. However, this type of material is helpful for projects that require ballistic protection.

Military and ballistic steel, however, is made specifically for military combat. As a result, these steels must meet specific chemical guidelines and undergo thorough testing at each design stage before approval.

Finally, military steel uses depend on the material’s chemical make-up and hardness. However, in recent years attempts have been made to find ways to use military materials for other civilian applications.

This is a step in the right direction regarding the sustainability of military grade materials.