At the end of the day it is all about Longevity, Reliability, Efficiency and Performance! With many Asian Countries offering cheap “knock-off” pump parts, it is tempting to purchase these items, but like everything in life, nothing is for free. When these cheaper parts do not last, cavitate, corrode, deteriorate, lose performance and efficiency, you do not save money; rather, you lose money!

The first time you have to overhaul your pump because of a leaking seal, bad bearing, loss of performance, or a vibration/imbalance problem you are looking at a substantial investment. An average 8” Suction x 6” Discharge Pump will cost approximate $8,000 to $10,000 to overhaul (NOT including Labor) because when a mechanical seal needs to be replaced, you also need to replace all the bearings, seals, worn casing rings, gaskets, sleeves under the seal face and maybe even the impeller if the mechanical seal failed as a result of excessive radial, or axial movement.

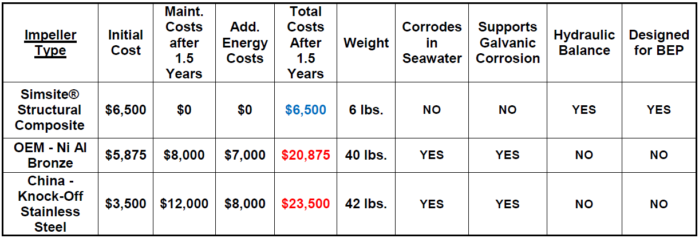

Let’s look at the following two examples: Customer A and Customer B both need an impeller & ring set for their main seawater cooling pumps…

Customer A purchased a “top of the line” SIMSITE® Structural Composite Impeller & Casing Rings Set for their main seawater cooling pump. The SIMSITE Impeller (12” Diameter x 5” Overhaul Width) and Casing Ring Set had a Purchase Price of $6500.00

Customer B purchased a “cheap knock-off” Impeller from China. Customer B paid only $3000 for the impeller and then another $500 for shipping from China for a total Purchase Price of $3500.00. Customer B thinks he/she saved $3,000.00

After only 1.5 years of continuous seawater operation:

Customer A’s pump is working fine, no bearing, or mechanical seal failures and the pump is operating very efficiently with no vibration.

Total Cost after 1.5 Years = $6500.00

Customer B’s pump on the other hand has had a bearing failure and a mechanical seal failure. The pump performance has deteriorated and the pump has a slight vibration from cavitation. The two overhauls cost $12,000.00 not including labor or loss of downtime.

Total Cost after 1.5 years of operation: $15,500.00

The reality is that Customer B did not save $3,000 by purchasing a cheaper impeller; rather, Customer B Lost $9000.00 and will continue to lose more money every year!

Additionally, Customer B’s impeller is inefficient and is losing 10% in energy efficiency because the cheaper metallic impeller is corroding, cavitating, suffering from performance deterioration, and is both mechanically and hydraulically imbalanced. Making matters worse, Customer B’s impeller is NOT operating at the Best Efficiency Point (BEP) making the pump inefficient. This loss of efficiency with the cheaper impeller inside this 50 HP Main Seawater Pump is costing Customer B another $9,000 per year! The total loss for Customer B is greater than $23,500!

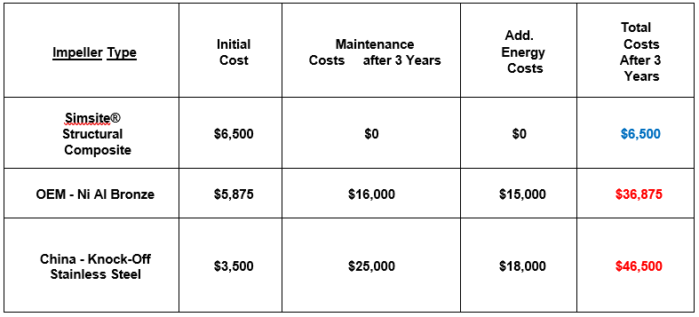

Total Costs after 3 years of Operation of a 50 HP Main Seawater Pump:

As you can see from the chart above, the knock-off Impeller from China cost the Customer $46,500 in Maintenance and Energy Costs and the OEM Impeller from the Pump Manufacturer has cost the Customer $36,875 in Maintenance and Energy Costs! Upgrading to Simsite® Impellers Improves Longevity, Reliability, Energy Efficiency and SAVES MONEY! Simsite® Impellers & Rings are the BEST SOLUTION!

John A. Kozel

PresidentSIMS PUMP Valve Company, Inc.

1314 Park Avenue

Hoboken, New Jersey 07030 USAOffice: 1-201-792-0600

Mobile: 1-201-323-6087

Email: simsite1@simsite.com