SIMSITE® DOUBLE SUCTION IMPELLERS

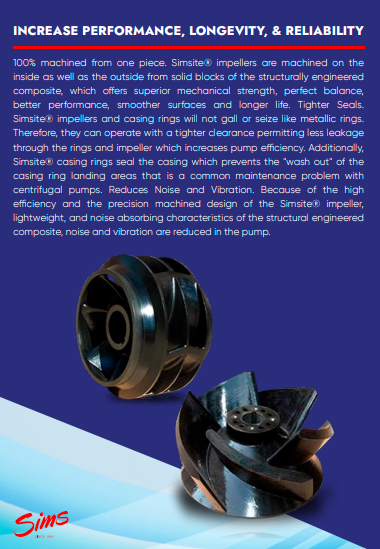

ImpellerStore is able to do this because our Simsite® Impellers are not cast or molded. Rather, Simsite® Impellers are machined on the outside as well as the inside on 5 to 8 axis machining centers.Simsite® Structural Composite Double Suction Impellers are Superior to Metallic Impellers because they are engineered to eliminate corrosion, erosion, vortexing, and cavitation problems that are inherent in metallic pump impellers!

Because our Simsite® Structural Composite Double Suction Impellers are 100% machined from a center axis position, the Simsite® Impellers are perfectly balanced both mechanically and hydraulically ( the vane passages are equally spaced, which is critical on Double Suction Impellers) and they remain balanced for the life of the impeller! This eliminates imbalance, excessive vibration, and cavitation problems that are inherent to cast and/ or molded impellers.

Simsite® Impellers are engineered to reduce or eliminate the effects of cavitation. Because Simsite® Impellers are precision machined from solid blocks of the structural composite, the impeller vane geometry can be engineered utilizing CFD (Computerized Fluid Dynamics) techniques and programs to eliminate the vortexing and cavitation problems experienced by cast or molded metallic impellers.

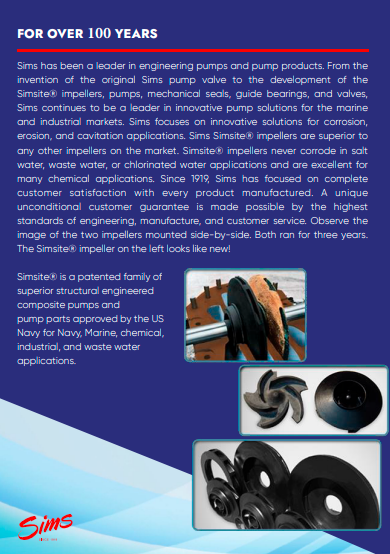

A TYPICAL DOUBLE SUCTION METALLIC IMPELLER WHICH IS SUFFERING FROM CAVITATION AS WELL AS CORROSION.

Simsite® Engineered composite impellers & Casing Rings offer even greater savings because they can be engineered to make the pump operating point the Best Efficiency Point (BEP) which significantly increases efficiency! (The farther away the pump operates from BEP, the lower the efficiency, and the higher the radial loading, movement, and vibration.) The machined vane surfaces provide smoother surface finishes, which allows for a lower coefficient of friction with self-lubricating qualities. Machined Structural Composite Impellers & Rings are 5 to 6 times lighter than metallic impellers and run on tighter wear ring to casing ring clearances.

This provides a reduction in mechanical losses as well as volumetric losses. Since machined composite impellers are perfectly balanced, both hydraulically and mechanically, and maintain this balance throughout the life of the pump, this reduces vibration and allows the pump to operate more efficiently which reduces downtime and operational costs. Engineered structural composite products also prove lightweight, reducing start-up load and shaft deflection. The result is an increase in the lifetime of Bearings, Seals, Rings, and Sleeves!

A PRECISION-MACHINED SIMSITE® DOUBLE SUCTION STRUCTURAL COMPOSITE IMPELLER WHICH WILL NEVER CORRODE IN SEA WATER, WASTE WATER, SEWAGE OR CHLORINATED WATER!

SIMSITE® Impellers & Casing Rings are the best Impellers & Casing Rings in the marketplace! The reason our Impellers are so good is because they are not cast, or molded.

ImpellerStore manufactures high quality, precision machined, upgraded, efficient, Impellers & Rings from SIMSITE®, a unique and patented structural composite. ImpellerStore Products are patented and completely different from any other Impellers & Casing rings in the market place because they are fully machined from a solid block of SIMSITE®, which never corrodes in sea water, brackish water, river water, chlorinated water, wastewater, and many other chemicals.

Our SIMSITE® Impellers and Casing Rings are truly unique because they are completely (100%) machined on the inside as well as the outside. The 5-axis to 8-axis precision machining makes our SIMSITE® impellers perfectly balanced both mechanically, and hydraulically – if an impeller is machined from one center position, there is NO Imbalance!

Furthermore, because our impellers do not corrode in seawater, brackish water, river water, wastewater, and many chemicals, they do not go into an imbalance and therefore they do not experience performance degradation like metallic products.

ImpellerStore SIMSITE® Impellers and Rings are excellent for new, repair, or retrofit applications. They are lightweight and virtually indestructible. Wear of other pump parts including the pump casing is greatly reduced because of the SIMSITE® Impeller’s perfect balance, lightweight, self-lubricating, sealing, and corrosion, erosion, & cavitation resistance. This means far less expense for the replacement of parts, downtime, and years of trouble-free performance.

ImpellerStore Simsite® Impellers and Rings are designed for Superior Hydraulic Performance because the Impellers are computer engineered, designed, and precision machined. The impeller vane geometry can be engineered to maximize efficiency and performance. Problems such as recirculation, radial thrust, and cavitation can be minimized, or eliminated by upgrading to Simsite® Impellers & Rings. Impeller vane shapes can easily be modified to provide the best vane shape for specific applications and performance requests.

It is all too common a problem — you purchased a pump for one specific performance and when you put the pump into service in your plant or ship, the pump operates at another point completely different from the original design point (BEP or best efficiency point) of the pump because of your system requirements. In addition to being very inefficient, when you operate the pump away from the original design point or BEP, it causes a multitude of problems. These problems include excessive noise and vibration, shaft oscillation, cavitation, premature wear, and failure of the mechanical seals, bearings, rings, sleeves, and impellers. In extreme cases, the shaft will break.

Sims Pump Valve Company

1314 Park Avenue

Hoboken, NJ 07030

201-792-06000

www.simsite.com

www.impellerstore.com

simspump@simsite.com

simsite@simsite.com