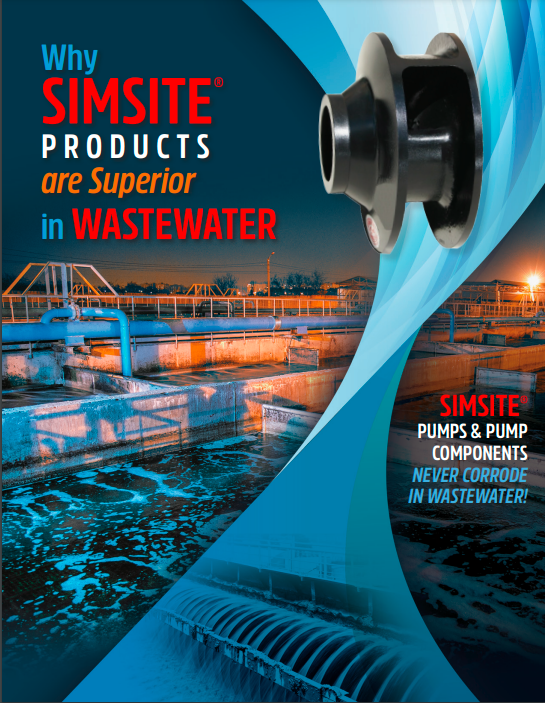

Metallic products corrode very quickly in wastewater. Also, many wastewater impellers are large, very heavy, unbalanced an often designed with “overhung” impellers. SIMSITE® Pumps, Impellers, and Pump Internals do not corrode in Wastewater and they also do not corrode in Sodium Hypochlorite!

SIMSITE® Impellers & Rings are lightweight, only 15% the weight of metal, perfectly balanced (both mechanically and hydraulically) and they remain balanced for the life of the impeller. Because SIMSITE® Impellers are machined from solid blocks of the patented SIMSITE®Structural composite from one center position they do not have to be balanced. This perfect balance combined with the light weight of the SIMSITE® Structural composited reduces shaft deflection, vibration, bearing loads and start up torque.

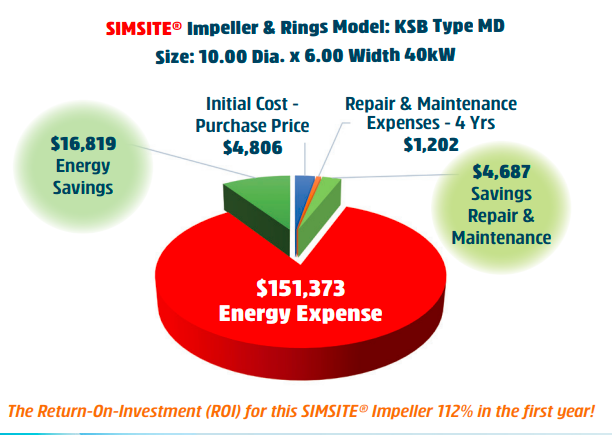

As a result of the many benefits of SIMSITE® Structural Composite Impellers, Casing Rings, and Complete Pumps; motors, bearings, sleeves, rings, and mechanical seals all last much longer!

Often Customers or Potential Customers complain about Mechanical Seal Failures, or Bearings Failures, and even Motor Failures. What most Customers do not realize is that they DO NOT have a Seal Problem, or a Bearing Problem, or a Motor Problem; rather, they have a hydraulics Problems caused by Clogging, Mechanical Imbalance, Hydraulic Imbalance, Radial Thrust Imbalance, or Improper Design, Repair, or Manufacture of the impeller!

All these problems are eliminated by upgrading to SIMSITE® Structural Composite Impellers & Casing Rings, or Complete SIMSITE® Pumps!

How SIMSITE® Impellers ELIMINATE Mechanical, Hydraulic and Radial Thrust Balance Problems:

SIMSITE® Impellers & Casing Rings do NOT CORRODE, or support ELECTROLYSIS (galvanic corrosion) in seawater, river water, sewage, chlorine, bromine, or wastewater, and they are 100% machined from one center position from solid blocks of SIMSITE® Patented Structural Composite, so SIMSITE® Impellers NEVER go into an imbalance. SIMSITE® Impellers are balanced both mechanically and hydraulically and remain balanced for the life of the pump! SIMSITE® Impellers & Casing Rings and Pumps are designed, engineered, and manufactured specifically for the system’s operating requirements, (Operating Point), making the operating point the pumps’ best efficiency point (BEP). That means there is substantially less radial and axial movement in the pump, which translates into longer life for:

a.) Bearings c.) Rings & Sleeves

b.) Mechanical Seals d.) Pump Motors

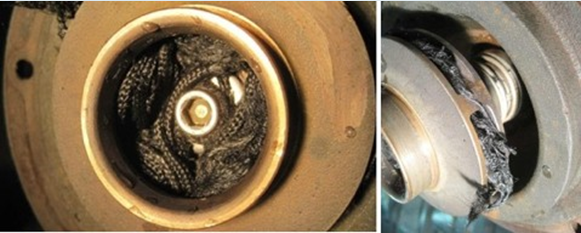

Centrifugal Pumps are often employed pumping processed aerobically digested sludge at Waste Water Treatment Plants. The problem is that hair and other stringy materials often get caught in the Pump Impeller. As the Impeller gets clogged, the pump performance deteriorates to zero. The clogged Impeller interrupts the treatment process and requires the operators to take the pump apart and clean it as often as a few times a day. The clogged Impeller interrupts the treatment process and requires the operators to take the pump apart and clean it as often as a few times a day in some cases

SIMS PUMP was tasked to investigate the possibility of re-designing a Metallic Enclosed Centrifugal Impeller and Manufacturing a Non-Clogging SIMSITE® Structural Composite Impeller to resolve the pump clogging problem. The customer specified that the Non-Clogging SIMSITE® Impeller must to fit into the existing Pump Casing and must match the performance of the original metallic impeller eliminating the need for a new electric motor

A new open-faced SIMSITE® Structural Composite Impeller was designed, built and tested. The SIMSITE® Impeller was tested with clear water to prove that the pump performance; and was tested again with 2” long 1/8” diameter nylon strings to simulate stringy materials in the fluid. The test clearly showed that the SIMSTE® Open Face Impeller was capable of pumping the strings without clogging, or performance degradation! The Pump with Enclosed Impeller was incapable of processing the same performance with the nylon strings

SIMSITE® Non-Clogging Impeller

Existing metallic centrifugal pumps can be upgraded, and even modified for difficult services by re-engineering the Impellers utilizing state-of-the-art computerized design, manufacturing techniques, and upgrading the pumps with SIMSITE® Structural Composite Impellers & Rings.

Any centrifugal pump can be upgraded by modifying the Pump or the Pump Impeller. Pump wastewater handling capability can be greatly improved by upgrading the impellers to SIMSITE® Structural Composite Impellers which are designed for Non-Clogging capabilities.

There are many different types of composites in the marketplace. Non-Structural Composites, Semi-Structural Composites, and Structural Composites. Non-Metallic Composites get their strength from the reinforcing fibers – so if the fibers are cut, the strength of the composite is also cut – resulting in a Semi-Structural Composite.

A structural composite is one in which the reinforcing fibers are not cut, chopped, or macerated. Since non-metallic composites get their strength from the reinforcing fibers, if you cut your fibers, you cut your strength. For example, the human body is a composite of bones, muscle tissue, organs, etc. If bones are removed, the person is unable to walk

or support themselves! If the bones are broken, the person also has no real strength and is limited in movement. That is why structural composites have far superior mechanical strength.

SIMSITE® Structural composite reinforcing fibers are continuously interwoven in a tri-dimensional weave, for which SIMS has a patent on material and process. Structural engineered composites, like SIMSITE® produce the highest mechanical properties and the greatest reliability.