HOBOKEN, NJ: The Sims Pump Company has been in business for over 100 years and is proud to offer a wide range of repair and maintenance services for all varieties of centrifugal pumps.

Centrifugal pumps are at the heart of many commercial, industrial, and public works processes. Because of their frequent use across multiple industries, pumps are often overlooked as a potential expense when not operating optimally, but they could also be seen as a source of enhanced productivity.

When something goes wrong with a centrifugal pump or impeller, the professional team of technicians and pump engineers at the SIMS PUMP Company have come to the rescue of many municipal, commercial, industrial, and marine clients.

The unparalleled level of service offered by the Sims Repair & Maintenance Division demonstrates the company’s dedication to improving the longevity and performance of pump systems. By enhancing a pump’s efficiency and reliability and eliminating issues related to erosion, corrosion, electrolysis, and cavitation, SIMS PUMP keeps their clients’ equipment running smoothly with minimal downtime.

SIMS has invested heavily in state-of-the-art equipment and facilities, while also hiring the most qualified pump specialists and repair team to provide the best pump servicing solutions. As a result, the repair and maintenance team at SIMS PUMP can accommodate any type of repair on the centrifugal pump and pump systems, whether in a vertical, horizontal, or submersible configuration.

The SIMS PUMP Repair and Maintenance Division performs a thorough appraisal of a pump’s condition to determine which repairs are necessary, while also inspecting it for unsuspected issues. By providing a full inspection on their customer’s pump systems, SIMS’ technicians quickly identify any and all issues to provide a plan to make repairs that meet the highest quality standards.

A SIMS Repair & Maintenance appraisal includes a complete report on the general and specific conditions of the pump. In addition to the written report, our technicians will provide digital photographs and measurements to identify mechanical damage. SIMS PUMP has full performance test capabilities to test the centrifugal pumps that have come in for repair and service.

Keeping pumps and impellers working properly can be challenging for companies that rely on pumps that are in constant operation. Whether operated in saltwater, river water, sewage, wastewater, chemicals, or chlorinated water; the maintenance and repair services offered by SIMS PUMP are designed to minimize downtime and prevent repeated repairs in the future.

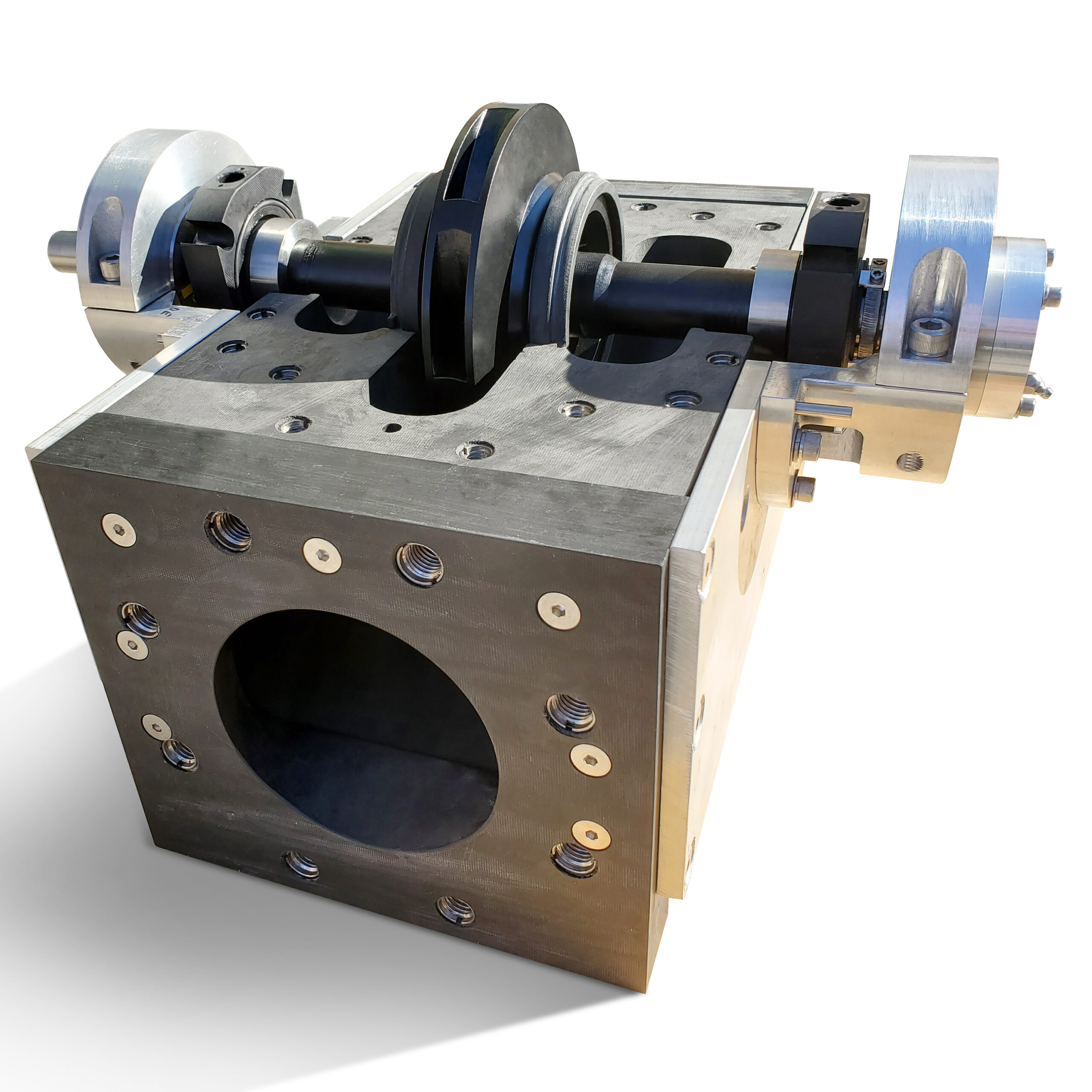

SIMS PUMP has the capability to reverse engineer and upgrade any pump, or pump part, for any centrifugal pump application, even if the pump is obsolete, or the pump manufacturer is no longer in business. The upgraded pumps and parts provide longevity, reliability, and higher energy efficiency.

In the event that a centrifugal pump or impeller needs to be replaced, the SIMS PUMP company can significantly reduce future maintenance costs by replacing and upgrading it with their corrosion-proof pumps, impellers, and line shaft bushings manufactured from their patented SIMSITE® Structural Composite. These innovative products never corrode in Seawater, Sewage or Waste Water allowing them to remain in continuous operation with minimal costs and downtime.

Known for their patented SIMSITE® Pumps, Impellers & casings Rings the SIMS PUMP Company has built its reputation on manufacturing pumps and pump parts that are more reliable and last much longer in corrosive environments.

SIMSITE® products have a long track record of being significantly more durable than bronze stainless steel, or duplex stainless steel. Unlike most other pump companies that offer only standard lines of pumps, SIMSITE® Pumps & Impellers are customs engineered in the United States to meet the customer’s unique performance demands.

SIMS PUMP has the unique ability to make the Customer’s Operating Point (OP) the Best Efficiency Point (BEP) substantially improving efficiency, reliability, and longevity! SIMSITE Pumps and Impellers prevent Performance Deterioration.

John A. Kozel

President

SIMS PUMP Valve Company, Inc.

1314 Park Avenue

Hoboken, New Jersey 07030 USA

Office: 1-201-792-0600

Mobile: 1-201-323-6087

Email: Simsite1@Simsite.com

SOURCE SIMS PUMP Valve Company, Inc.

Related Links