Summary

Our first ingredient, Citri-Fi®, is a high water binding ingredient manufactured from citrus waste and sold under a license agreement by our associated company, Fiberstar, Inc. Citri-Fi® has generated more than $50 million in global sales to date and provides us with an excellent source of on-going revenue from licence fees. Worldwide demand for Citri-Fi® continues to grow so rapidly that Fiberstar has just completed the tripling of its production capacity.

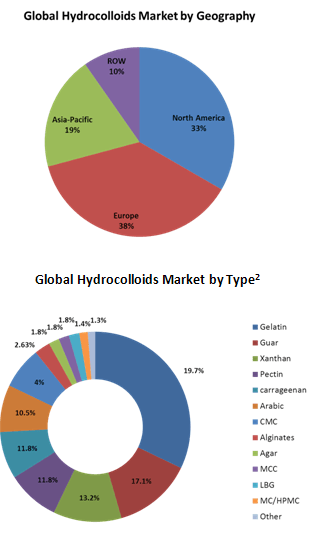

Now we are ready to execute our 3-stage plan to commercialize and manufacture our own technology called Modi-Fi™, an all-natural thickening and suspending ingredient aimed at the $1 billion addressable global food ingredient market and the $5 billion US natural polymer market for industrial applications. This technology won’t be licenced, we are going take full benefit from this exciting innovation as owners and manufacturers. Here’s the plan:

Stage 1: 2015—Complete technology development and pilot scale-up.

Stage 2: 2016—Build a small demonstration and commercial production plant (1/10th scale)

2017-18—Small commercial production @ $4.5 million revenue per annum.

Stage 3: 2018—Build a full-scale plant (production and sales)

2019-2021—Full-scale commercial production projecting over $45 million revenue per annum.

+1-786-628-7980

+1-786-628-7980

Sign Up/Sign In

Sign Up/Sign In