Tubeless made easy – no more flat tires

Sick of flat tires when biking? Us too. That’s why we invented milKit, the Swiss made solution for easy measuring and refilling sealant in tubeless tires – which means you can spend less time fixing tires and more time on the bike.

Help us to boost visibility for milKit and get to the market fast!

Christoph Sauser: “The milKit valves are great as they don’t clog anymore.”

World Champion, World Cup Champion, Olympic Medalist

benefits at a glance

benefits at a glance

- easy to use kit for tubeless systems

- no more dirty hands

- no more valve clogging

- makes tubeless systems reliable

milKit makes tubeless tires maintenance clean, quick and simple. Enjoy a safe ride!

Simple and reliable for a safe ride

milKit is a new system for measuring and refilling sealant in tubeless tires. Unlike traditional tires, tubeless tires don’t use an inner tube. The tire seals directly on the rim. A sealant (milk) is filled into the tire before installation and seals punctures and leaks. The main benefit of tubeless systems is being able to ride at low air pressure for better traction without getting flats, because there is no tube to pinch. Plus you save weight. The maintenance of tubeless tires was tedious – until now. milKit allows a precise and easy measurement of the sealant without removing the tire from the rim and releasing the air pressure. milKit makes riding tubeless systems reliable, simple and safe – plus no more dirty hands.

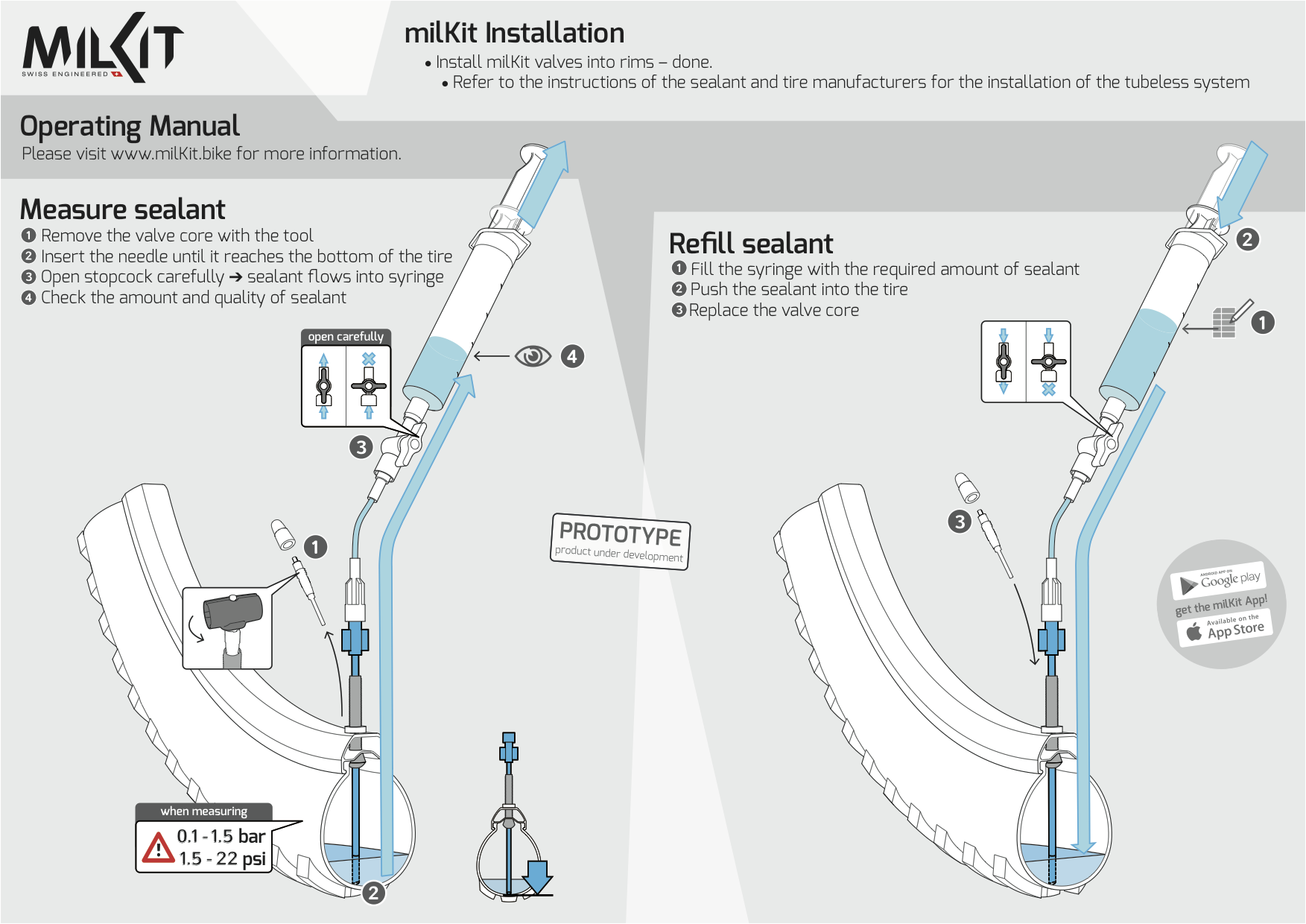

How to use milKit

Check out our product video to see how easy tubeless system maintenance is with milKit.

- Push the applicator into the valve

- Let the sealant flow into the syringe and check remaining sealant

- Fill the missing amount of sealant into the tire

|

Available milKit packages

- 2 milKit valves: No more valve clogging

- milKit compact: 2 milKit valves

+ measuring and refilling device

- milKit plus: milKit compact + sealant

|

|

Approved by the pros

We received very positive feedbacks to our prototypes from the major players of the tubeless industry including tire manufacturers and sealant producers. Professional mountain bikers like mountain biking legend Thomas Frischknecht tested and liked our prototypes. milKit was also tested under very rough conditions at Cape Epic 2015, one of the most prestigious mountain bike races in the world. Race champion Christoph Sauser: “The milKit valves are great as they don’t clog anymore.”

Markus Binggeli also successfully approved our valves at the race.

Foto© Markus Binggeli/Cape Epic

The history of milKit

The idea for milKit was born during a mountain bike trip in the middle of nowhere around Moab (USA) – with a flat tubeless tire due to dried out sealant. A problem that those of you that ride tubeless will understand, as you never really know how much sealant is left in the tire, unless you deflate and dismount your tire, which no one really wants to do. That’s why the Swiss mountain bike addict and product development engineer Pius Kobler started to puzzle over an easy to use solution. Now, one year after the first homemade prototypes, countless test rides and the foundation of Sport Components Ltd. with another biking enthusiast and experienced company founder Sven Rizzotti, milKit is ready to be launched to the market.

|

|

|

|

| Pius Kobler, CEO |

Sven Rizzotti, Sales |

Anna-Julia Lingg, PR Marketing |

Be milKit

We’ve been working hard to create the best possible product. Prototypes work great, production can start. Creating the production tools costs more than 65’000 USD. With this campaign we try to finance a part of these expenses. Help us to get milKit to the market fast and spread this project to your mountain biking buddies. Together we boost visibility for milKit. Be milKit!

Risks and challenges

To minimize our and your risk we work with professional partners in Switzerland and Italy, virtually at our doorstep. milKit guarantees Swiss quality.